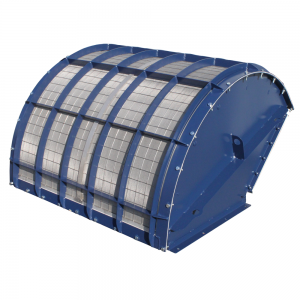

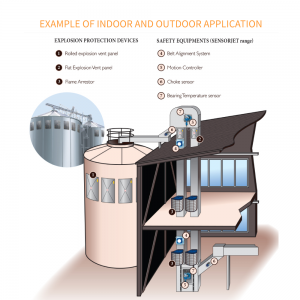

To protect indoor machinery the model, VQ, guarantees flameless venting and dust protection. No burnt or unburnt dust passes off. Even high temperature is reduced to a minimum. During normal venting an explosion is freely discharged, allowing flames and dust to exit from the process vessel. When the process is located indoors, ducts are generally used to convey the explosion outside the building. However, the cost and options of implementing explosion vents and ducts are limited.

Model VQ is an ATEX approved flameless explosion vent. It is used with great effect indoors and outdoors. It is the best and easiest solution instead of cumbersome and expensive solutions with pipe installations to the open air. The VQ provides low pressure resistance effectively eliminating flame and heat emissions thereby easing indoor installation and positioning of relevant machinery.

VQ is rectangular and supplied with a standard rectangular bursting panel and it is available in different sizes. A burst sensor is included in the delivery. Model VQ is certified by the French notified body INERIS and will comply with the latest standard for Flameless Explosion Venting Devices: EN 16009 : 2011.

SPECIFICATIONS: VQ LW AND VQ HW FLAMELESS EXPLOSION VENTING

| FEATURES | |||||||||||||

| Dust | Kst value | Follow the features of the explosion vent panel of type VL or VD or VFlex used | |||||||||||

| Dust kind | Organic dust. | ||||||||||||

| Gas | Kg value: | Follow the features of the explosion vent panel of type VL or VD or VFlex used | |||||||||||

| Gas kind | Gas group: IIA and not hybride mixing | ||||||||||||

| Safety features | If the discharge is ATEX zone : 21 or 22 | - MIE = minimum ignition energy : MIE > 10 mJ - MIT = minimum ignition temperature : MIT > 400 °C |

|||||||||||

| If the discharge zone is out of ATEX zone | - MIE = minimum ignition energy : MIE > 1 mJ - MIT = minimum ignition temperature : MIT > 250 °C |

||||||||||||

| Particule size | DV0.1 ≥ 6 µm | ||||||||||||

| Pmax : | ≤ 10 bar | ||||||||||||

| Vent panel | Static activation pressure | Pstat: Follow the features of the vent panel of type VL, VD or VFlex | |||||||||||

| Vessel to be protected | Max pressure (VQ HW) | Pred max ≤ 2.3 bar until VIGILEX VQ size: 586x920 (5360cm²) Pred max ### 1.85 bar until VQ size 113x1130 (12720 cm²) |

|||||||||||

| Max pressure (VQ LW) | Pred max ≤ 0.5 bar until VIGILEX VQ size: 1130x1130 (12720cm²) | ||||||||||||

| Max process temperature | ≤ +140°C (The maximum operating temperature is limited by the maximum temperature of the opening detector used). | ||||||||||||

| Standards and certificates | EN 1009-2011 | Flameless explosion venting devices | |||||||||||

| INERIS 14ATEX0049X | UE type examination certificate according to EN 16009-2011 | ||||||||||||

| INERIS 08ATEXQ406 | Production quality assurance Notification | ||||||||||||

| ISO9001-2015 | Quality management systems | ||||||||||||

| GENERAL DIMENSIONS | |||||||||||||

| VQ HW / VQ LW | Nominal panel size | Nominal panel area | Weight: VQ HW | Weight: VQ LW | Fixing Bolt Nbr | ||||||||

| 170x470 | 170 x 470 mm / 7 x 19 inch | 0,0785 m² / 0,845 sq ft | 59 kg | 48 kg | 20 M10x30 | ||||||||

| 270x458 | 270 x 458 mm / 11 x 18 inch | 0,1220 m² / 1,315 sq ft | 74 kg | 60 kg | 22 M10x30 | ||||||||

| 300x500 | 300 x 500 mm / 12 x 20 inch | 0,1480 m² / 1,595 sq ft | 82 kg | 67 kg | 24 M10x30 | ||||||||

| 305x610 | 305 x 610 mm / 12 x 24 inch | 0,1840 m² / 1,980 sq ft | 96 kg | 79 kg | 26 M10x30 | ||||||||

| 350x650 | 350 x 650 mm / 14 x 26 inch | 0,2250 m² / 2,425 sq ft | 101 kg | 84 kg | 26 M10x30 | ||||||||

| 490x590 | 490 x 590 mm / 19 x 23 inch | 0,2870 m² / 3,085 sq ft | 123 kg | 94 kg | 32 M10x30 | ||||||||

| 610x610 | 610 x 610 mm / 24 x 24 inch | 0,3695 m² / 3,975 sq ft | 147 kg | 112 kg | 32 M10x30 | ||||||||

| 457x890 | 457 x 890 mm / 18 x 35 inch | 0,4040 m² / 4,349 sq ft | 152 kg | 117 kg | 34 M10x30 | ||||||||

| 586x920 | 586 x 920 mm / 23 x 36 inch | 0,5360 m² / 5,770 sq ft | 178 kg | 136 kg | 42 M10x30 | ||||||||

| 645x1130 | 645x1130 mm/ 25 x 44 inch | 0,7250 m² / 7,804 sq ft | 240 kg | 222 kg | 34 M10x30 | ||||||||

| 920x920 | 920 x 920 mm/ 36 x 36 inch | 0,8425 m² / 9,070 sq ft | 641 kg | 317 kg | 50 M10x30 | ||||||||

| 1130x1130 | 1130x1130 mm/ 44 x 44 inch | 1,2720 m² / 13,694 sq ft | 802 kg | 442 kg | 62 M10x30 | ||||||||

| PROTECTED VESSEL VOLUME BY DEVICE: Vmax,FV | |||||||||||||

| Size | 170x470 | 270x458 | 300x500 | 300x500 | 350x650 | 490x590 | 610x610 | 457x890 | 586x920 | 645x1130 | 920x920 | 1130x1130 | |

| ATEX 21 & 22 | 2,0 m³ | 3,1 m³ | 3,7 m³ | 4,6 m³ | 5,6 m³ | 7,2 m³ | 9,2 m³ | 10,0 m³ | 13,4 m³ | 18,0 m³ | 21,0 m³ | 21,0 m³ | |

| Not ATEX | 2,1 m³ | 3,3 m³ | 4,0 m³ | 5,0 m³ | 6,1 m³ | 7,8 m³ | 10,0 m³ | 11,3 m³ | 15,0 m³ | 18,0 m³ | 21,0 m³ | 21,0 m³ | |

| VQ HW | Pred.max | <2,3 bar | <1,85 bar | ||||||||||

| Pstat.max | ≤500 mbar | ≤500 mbar | |||||||||||

| VQ LW* | Pred.max | <0.5 bar | <0.5 bar | ||||||||||

| Pstat.max | ≤300 mbar | ≤300 mbar | |||||||||||

| * the VIGILEX VQ LW is equipped with two inspection windows (Pred, max <0.5bar). | |||||||||||||

INSTALLATION AND USE INSTRUCTIONS

View or download the installation and use instructions for the VIGILEX VQ flameless explosion venting by clicking the button below (opens in new brower tab).

DIMENSIONS AND WEIGHT TABLE

View or download the dimension and weight table for the VIGILEX VQ flameless explosion venting by clicking the button below (Opens in new browser tab).

2D TECHNICAL DRAWING (350x650)

View or download the 2D technical drawing for VIGILEX VQ flameless explosion venting by clicking the button below (Opens in new browser tab).

3D TECHNICAL DRAWING (350x650)

View or download the 3D technical drawing for VIGILEX VQ flameless explosion venting by clicking the button below (Opens in new browser tab).

+45 88 63 89 00

+45 88 63 89 00